KSMETAL

KSMETAL

KSMETAL

KSMETAL

Greetings.

KSMETAL is a casting company specializing in the production of copper alloy non-ferrous metal materials.

We provide a One-Stop Solution from design optimized for customer's usage conditions to prototyping and mass production.

We will always repay you with excellent quality. Thank you.

CEO of KSMETAL

Heung-Gil Kim

Major product lines produced with high-quality materials and precise technology.

Alloy materials for oilless bearings with high strength, hardness, wear resistance,

corrosion resistance, and toughness.

Used for medium-high speed and high load bearings and pistons due to excellent lubricity, wear resistance, and pressure resistance.

Various copper alloy non-ferrous casting parts for general industrial machinery and facilities

(Pump casing, Impeller, Bracket, etc.)

Click the tabs below to check detailed chemical composition, mechanical properties, characteristics, and applications.

| Type | Symbol |

Chemical Composition (%) | Mechanical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Sn | Zn | Pb | Fe | Al | Mn | Ni | P | Tensile (N/mm²) | Elong. (%) | Hardness (HB) |

||

| High Strength Brass (HBsC) |

CAC301 | 55~60 | - | 33~42 | - | 0.5~1.5 | 0.5~1.5 | 0.1~1.5 | - | - | 430↑ | 20↑ | - |

| CAC302 | 55~60 | - | 30~42 | - | 0.5~2.0 | 0.5~2.0 | 0.1~3.5 | - | - | 490↑ | 18↑ | - | |

| CAC303 | 60~65 | - | 22~28 | - | 2.0~4.0 | 3.0~5.0 | 2.5~5.0 | - | - | 635↑ | 15↑ | 165↑ | |

| CAC304 | 60~65 | - | 22~28 | - | 2.0~4.0 | 5.0~7.5 | 2.5~5.0 | - | - | 755↑ | 12↑ | 200↑ | |

| Bronze (BC) |

CAC401 | 79~83 | 2.0~4.0 | 8.0~12.0 | 3.0~7.0 | - | - | - | - | - | 165↑ | 15↑ | - |

| CAC402 | 86~90 | 7.0~9.0 | 3.0~5.0 | - | - | - | - | - | - | 245↑ | 20↑ | - | |

| CAC403 | 86.5~89.5 | 9.0~11.0 | 1.0~3.0 | - | - | - | - | - | - | 245↑ | 15↑ | - | |

| CAC406 | 83~87 | 4.0~6.0 | 4.0~6.0 | 4.0~6.0 | - | - | - | - | - | 195↑ | 15↑ | - | |

| CAC407 | 86~90 | 5.0~7.0 | 3.0~5.0 | 1.0~3.0 | - | - | - | - | - | 215↑ | 18↑ | - | |

| Phosphor Bronze (PBC) |

CAC502A | 87~91 | 9.0~12.0 | - | - | - | - | - | - | 0.05~0.2 | 195↑ | 10↑ | 60↑ |

| CAC502B | 87~91 | 9.0~12.0 | - | - | - | - | - | - | 0.15~0.50 | 295↑ | 5↑ | 80↑ | |

| CAC503B | 84~88 | 12.0~15.0 | - | - | - | - | - | - | 0.15~0.50 | 265↑ | 3↑ | 90↑ | |

| Leaded Bronze (LBC) |

CAC602 | 82~86 | 9.0~11.0 | - | 4.0~6.0 | - | - | - | - | - | 195↑ | 10↑ | 65↑ |

| CAC603 | 77~81 | 9.0~11.0 | - | 9.0~11.0 | - | - | - | - | - | 175↑ | 7↑ | 60↑ | |

| CAC604 | 74~78 | 7.0~9.0 | - | 14.0~16.0 | - | - | - | - | - | 165↑ | 5↑ | 55↑ | |

| CAC605 | 70~76 | 6.0~8.0 | - | 16.0~22.0 | - | - | - | - | - | 145↑ | 5↑ | 45↑ | |

| Aluminum Bronze (AlBC) |

CAC701 | 85~90 | - | - | - | 1.0~3.0 | 8.0~10.0 | 0.1~1.0 | 0.1~1.0 | - | 440↑ | 25↑ | 80↑ |

| CAC702 | 80~88 | - | - | - | 2.5~5.0 | 8.0~10.5 | 0.1~1.5 | 1.0~3.0 | - | 490↑ | 20↑ | 100↑ | |

| CAC703 | 78~85 | - | - | - | 3.0~6.0 | 8.5~10.5 | 0.1~1.5 | 3.0~6.0 | - | 590↑ | 15↑ | 150↑ | |

| CAC704 | 71~84 | - | - | - | 2.0~5.0 | 6.0~9.0 | 7.0~15.0 | 1.0~4.0 | - | 590↑ | 15↑ | 160↑ | |

| Type | Symbol | Characteristics | Applications |

|---|---|---|---|

| High Strength Brass (HBsC) |

CAC301 | High strength, hardness, corrosion resistance, and toughness. | Marine propellers, Bearings, Valve seats, Lever arms |

| CAC302 | High strength and wear resistance. Superior rigidity to CAC301. | Propellers, Bearing retainers, Valve seats, Special cylinders | |

| CAC303 | Exceptionally high strength and hardness. Good wear resistance under heavy loads. | Low speed/Heavy load sliding parts, Large valves, Stems, Worm gears | |

| CAC304 | Highest strength and hardness among high strength brass castings. | Heavy load support plates, Bearings, Bushings, Nuts | |

| Bronze (BC) |

CAC401 | Good melt flow and machinability (General bronze). | Bearings, Nameplates, General machine parts, Valves |

| CAC402 | Good pressure resistance, wear resistance, corrosion resistance, and mechanical properties. | Bearings, Sleeves, Bushings, Pump bodies, Gears, Marine parts | |

| CAC403 | Good pressure and wear resistance. Superior corrosion resistance to CAC402. | Bearings, Sleeves, Impellers, Valves, Gears, Electric device parts | |

| CAC406 | Excellent pressure resistance, wear resistance, machinability, and castability. | Valves, Pump bodies, Faucets, Bearings, General machinery | |

| CAC407 | Better mechanical properties than CAC406. | Bearings, Small pumps, Valves, Fuel pumps | |

| Phosphor Bronze (PBC) |

CAC502A | Excellent corrosion and wear resistance. | Gears, Worm gears, Bearings, Bushings, Sleeves, Impellers |

| CAC502B | Good corrosion and wear resistance with dense structure (Mold/Continuous casting). | Gears, Worm gears, Bearings, Bushings, General machine parts | |

| CAC503B | High hardness, good wear resistance, and dense structure. | Sliding parts, Hydraulic cylinders, Sleeves, Various rollers | |

| Leaded Bronze (LBC) |

CAC602 | Good pressure and wear resistance. Suitable for medium-speed/heavy-load bearings. | Medium-high speed/heavy load bearings, Cylinders, Valves |

| CAC603 | Suitable for bearings with high surface pressure. Good conformability. | Medium-high speed/heavy load bearings, Large engine bearings | |

| CAC604 | Good conformability. Used for backing plates of white metal. | Medium-high speed/medium load bearings, Vehicle bearings | |

| CAC605 | Especially good conformability and seizure resistance among leaded bronze castings. | Medium-high speed/low load bearings, Engine bearings | |

| CAC606 | Suitable for bearings with irregular motion or imperfect lubrication. | Light load high speed bushings, Bearings, Vehicles | |

| Aluminum Bronze (AlBC) |

CAC701 | High strength and toughness. Resistant to bending. Excellent corrosion/wear resistance. | Acid-resistant pumps, Bearings, Bushings, Gears, Valve seats |

| CAC702 | High strength, good corrosion and wear resistance. | Small marine propellers, Gears, Bearings, Bolts | |

| CAC703 | Suitable for large castings. Especially high strength and corrosion resistance. | Marine propellers, Impellers, Valves, Gears, Pumps | |

| CAC704 | Suitable for simple large castings. High strength and excellent corrosion resistance. | Marine propellers, Sleeves, Gears, Chemical equipment | |

Optimized production facilities for Centrifugal Casting, Sand Casting, and Investment Casting

| Melting | High Frequency Induction Furnace (1 ton) - 2 Units |

|---|---|

| Casting | Centrifugal Casting Machine - 4 Horizontal Units |

| Machining | Universal Lathes (∅0 ~ 2000) - Multiple Units, Milling Machine (9 No. 2700X950mm) |

| Inspection | Spectrometer, Hardness Tester (HB), Surface Roughness Tester |

We input carefully selected raw materials (ingots, scraps) and melt them in a high-frequency induction furnace.

Additional mixing alloys such as components and alloy ratios can be tailored to customer requirements.

A method where molten metal is poured into a sand mold. Suitable for simple shapes or small/medium/large product production, and facilitates small quantity batch production.

Produces materials with very dense structure and excellent mechanical properties using the centrifugal force of high-speed rotation.

High dimensional precision and beautiful surface finish minimize machining processes. Effective for complex designs or small/medium quantity specialized parts.

| Centrifugal Mold Specification List (SIZE : Ø × L) | ||

|---|---|---|

| Ø130 × 800L | Ø310 × 800L | Ø490 × 700L |

| Ø140 × 800L | Ø320 × 800L | Ø500 × 700L |

| Ø150 × 800L | Ø330 × 800L | Ø510 × 700L |

| Ø160 × 800L | Ø340 × 800L | Ø520 × 700L |

| Ø170 × 800L | Ø350 × 800L | Ø530 × 700L |

| Ø180 × 800L | Ø360 × 800L | Ø540 × 700L |

| Ø190 × 800L | Ø370 × 800L | Ø550 × 700L |

| Ø200 × 800L | Ø380 × 800L | Ø560 × 700L |

| Ø210 × 800L | Ø390 × 800L | Ø570 × 700L |

| Ø220 × 800L | Ø400 × 700L | Ø580 × 700L |

| Ø230 × 800L | Ø410 × 700L | Ø590 × 700L |

| Ø240 × 800L | Ø420 × 700L | Ø600 × 700L |

| Ø250 × 800L | Ø430 × 700L | Ø610 × 700L |

| Ø260 × 800L | Ø440 × 700L | Ø620 × 700L |

| Ø270 × 800L | Ø450 × 700L | Ø630 × 700L |

| Ø280 × 800L | Ø460 × 700L | Ø640 × 700L |

| Ø290 × 800L | Ø470 × 700L | Ø650 × 700L |

| Ø300 × 800L | Ø480 × 700L | |

The cast material is subjected to primary rough machining (including machining allowance) using universal lathes and milling machines.

Only qualified products that have passed strict quality control processes such as final dimensional inspection, roughness measurement, and porosity inspection are packed and shipped to customers.

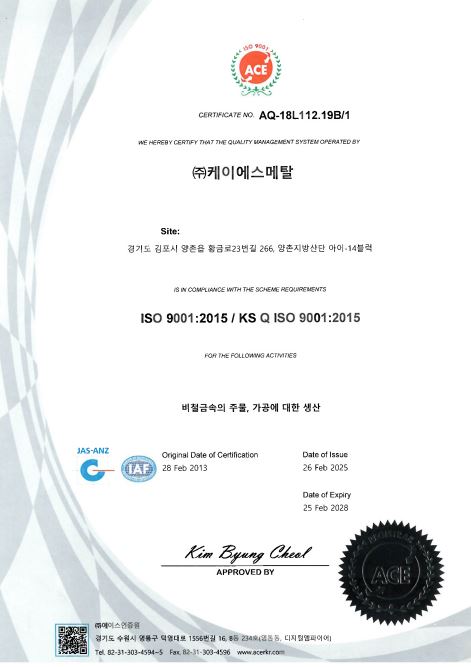

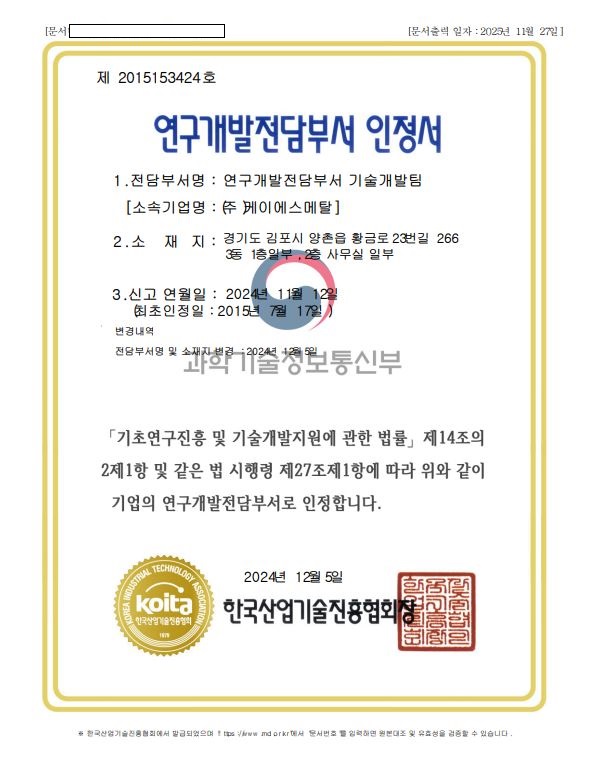

We gain customer trust through proven quality and continuous technological development.

Quality Management System

Research & Development

Casting Method Patents

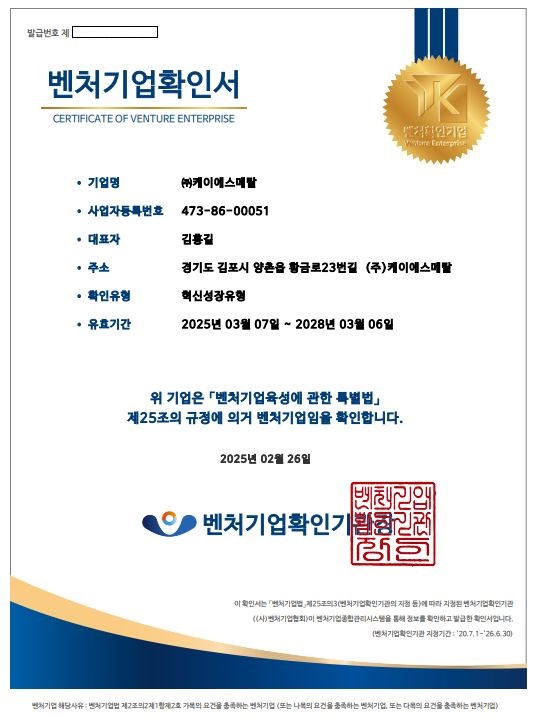

Venture Business, Root Industry, etc.

Feel free to contact us anytime for inquiries. We will respond promptly.

* Please make a reservation by phone before visiting the factory.